Static Neutralization Equipment/Ionizers

| ・Potential amplitude of 25 V or less with the dual AC type (At an installation height of 300 mm) ・Rapid neutralization of static electricity by a feedback sensor ・Reduction of adjustment and maintenance labor by an auto balance sensor ・Simple operation: Can be controlled by powering the ionizer ON (Standard type) ・Setting ionizer with remote controller ・Transition wiring may be used. ・High speed static neutralization cartridges and energy saving static neutralization cartridges are available. ・3 types of emitter cartridges High speed static neutralization cartridge Energy saving static neutralization cartridge Energy saving high-efficiency cartridge |

| Series | Type | Ion generation method | Ion balance |

|---|---|---|---|

| IZS42 | Dual AC type | Corona discharge type | ±30V |

| IZS41 | Feedback sensor type | Corona discharge type | ±30V |

| IZS40 | Standard type | Corona discharge type | ±30V |

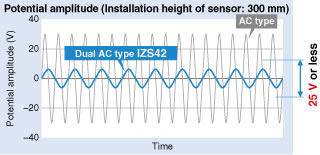

Dual AC Type IZS42 Series (Potential amplitude reduction specification)

Potential amplitude: 25 V or less 80% reduction compared to the existing model

(Compared to the IZS31 series at an installation height of 300 mm)

The potential amplitude can be reduced with SMC’s original dual AC type sensor.

Static neutralization in consideration of damage to a device which is sensitive to electrostatic discharge (ESD) can be achieved.

The potential amplitude generated in the applicable workpiece is reduced even if the workpiece is mounted within close proximity of the ionizer.

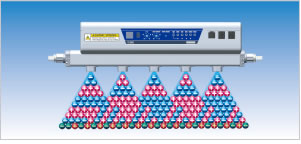

Implementation of our original dual AC type

Dual AC type IZS42

+ ions and − ions are dis-charged at the same time to allow the + and − ions to reach the workpiece evenly, thereby reducing the potential amplitude.

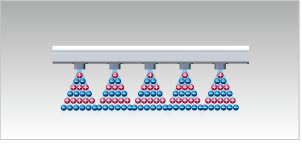

AC type

+ ion and − ion layers reach the workpiece alternately, which increases the potential amplitude.

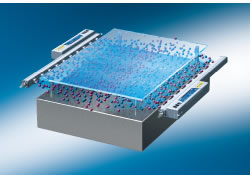

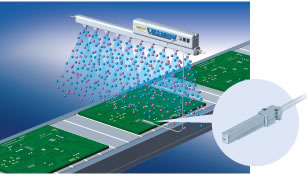

For the static neutralization of glass substrates

Prevents the breakage of glass substrates by the static electricity generated when the substrate is lifted from the surface plate

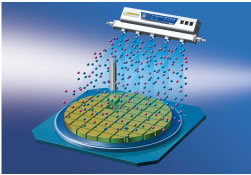

For the static neutralization of electric substrates

Prevents the breakage of electric substrates by the static electricity generated when the substrates are picked up after dicing

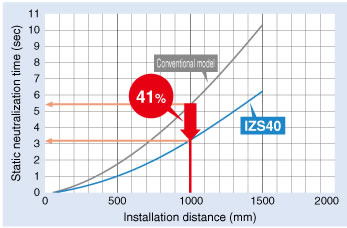

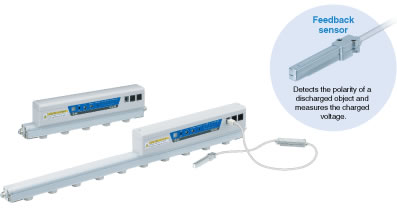

|Feedback Sensor Type IZS41 Series (High speed static neutralization specification)

Rapid static neutralization by a feedback sensor

Note)An auto balance sensor is installed.

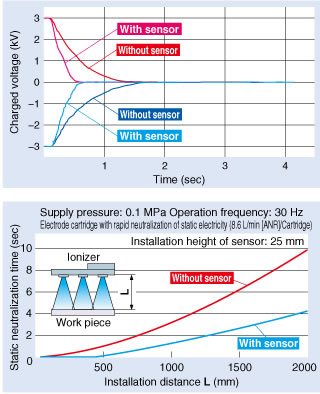

The discharge speed can be increased by using a feedback sensor (option) to detect the workpiece's electrostatic potential and continuously emit ions of the opposite polarity.

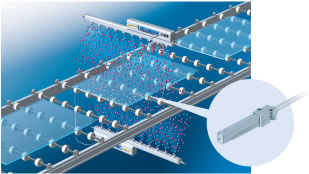

For the static neutralization of electric substrates

・Prevents element disruption due to discharge

・Prevents the adhesion of dust

For the static neutralization of glass substrates

・Prevents breakage due to adhesion and discharge

・Prevents the adhesion of dust

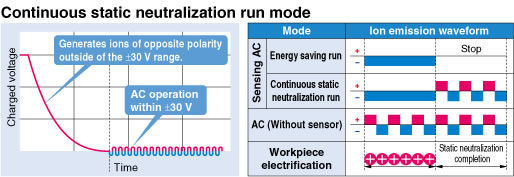

The operating mode after static neutralization (when electrostatic potential: within ±30 V) can be selected.

■Energy saving mode

Stops generating ions after static neutralization to reduce power consumption

■Continuous static neutralization mode

After static neutralization, the ionizer continues to neutralize static electricity in AC mode while maintaining the electrostatic potential within ±30 V.

Ionizer/Bar Type IZS40/41/42

- Product Code: IZS40/41/42 Ionizer/Bar Type

- Availability: In Stock