Blow Guns

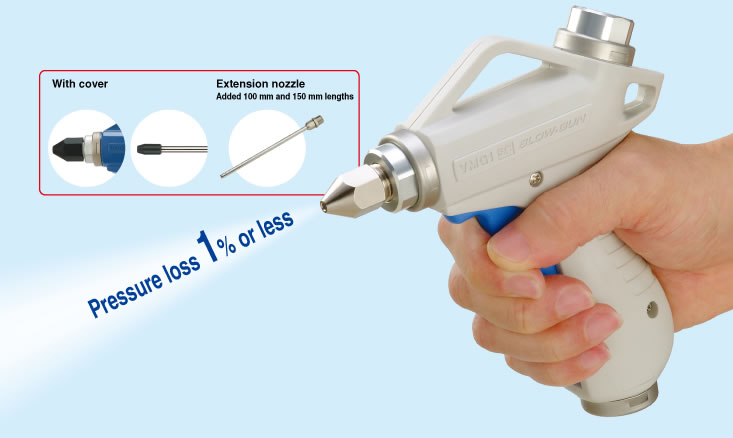

| ・A 20% reduction in power consumption can be achieved with the SMC “Blow gun” + “S coupler” + “Coil tube.” ・Pressure loss: 1% or less (Nozzle size: ø2.5) ・Available nozzles: Male thread nozzle, High efficiency nozzle with male thread, Low noise nozzle with male thread, Copper extension nozzle ・Flow Rate Adjustment Function (-X54) |

| Series | Port size | Operating pressure range (MPa) | Effective area (mm2) | Nozzle port size |

|---|---|---|---|---|

| VMG | Rc,NPT,G 1/4,3/8 | 0 to 1.0 | 30 | Rc1/4 |

| ・SMCの [ブローガン]+[Sカプラー]+[コイルチューブ] で消費電力を20%削減 ・圧力損失1%以下(ノズル径:ø2.5) ・適用ノズル おねじ付ノズル、おねじ付高効率ノズル。 おねじ付低騒音ノズル、銅管ロングノズル。 ・流量調整機能付(-X54) |

the SMC "Blow gun" + "S coupler" + "Coil tube"

*10% reduction with the "Blow gun (VMG)" only

The electricity used by compressors for air accounts for approximately 20% of that consumed by the entire factory. Also, 70% of the air consumed in the process is used for air blowing. SMC blow guns have minimal pressure loss compared with conventional models, so they can achieve equivalent performance at lower pressures and with less volume of air consumption. As a result, it is possible to achieve a 20% reduction in power consumption.

Not affected by supply pressure, assured operability

When using this product even at a high pressure, the same gripping force is required as for a lower pressure due to the unique balance-poppet construction.

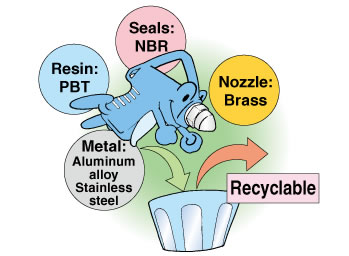

Components are separable.

Environmentally friendly

Resin parts are inscribed with the name of the material.

Additionally, all parts can be separated by material.

Use of shock-resistant resin

Shock-resistant resin is used in the main body. No cracks, breaks or other damage occurred in a drop test from a 2-meter height or in a human stomp test.

Tags: Blow Gun VMG